share posts

Friday, January 29, 2016

Thursday, January 28, 2016

Why Stock Clearance Sale is good for managing Inventory

For a retailer, the best way to ensure you continue to stock latest products and get your items moving is to ensure you continue to de-clutter your store so only the best merchandise remains.

This is more so especially for retail stores as " life cycles for fashion " are quick and abrupt. It is important for a retailer to get some of your investment back before it is totally worthless.

Many merchants are just hesitant to markdowns, and it is unnecessary. Your money is already gone; holding on to it just ties you to the past and all your are left with " stuff that will not sell as time grows by" and especially in apparel trade. If the clothes lying on your shelf has not sold for the last 5 months, chances are it may never get sold in the coming 6 months.

The best way to get rid of them is a "stock clearing sale" as you don't want to " have excess inventory" when you are just waiting for the latest stocks to arrive.. knowing that those will sell well

But many retailers feel that they must get back whatever they paid for their inventory, no matter how many years ago the merchandise first arrived in their store. This thinking is murder on their cash flow.

Some more retailers feel there will always be a demand for a part or accessory to a model or product, even if that product is no longer sold. Maybe on Ebay, but not on your display shelves.

inventory being like apple and milk and the more they sit there doing nothing ... the more are the chances of them getting spoiled.

Unlike Humans.. whose power of thinking and rationalizing gets better with age. Merchandise Doesn’t Get Better With Age. It only stops you from getting better returns

Too many retailers avoid aggressively clearing out old merchandise either because they feel they will lose money when they sell it, or it’s too complicated to know what to clear out. Neither is true. If merchandise is old, you’ve already lost the money. The fact it is sitting on your display shelves doesn’t make that any less true, but it does make your entire store look dated, out-of-touch or just plain old.

Global Auto Suppliers: Toyota

|

OEM FOR TOYOTA TACOMA

wind adhesive : Yokohama industries

Pedestrian protection absorber : shape

Oil Cap:miniature precision industries

Power Steering Feed Tunes: Yokohoma industries

Hydraulic Power Steering Pumps:Koyo

Fog Lamp : North American Lighting

Front Suspension Coil Spring : Nasco

Aluminium Wheel : Superior Industries

Electronic Locking Differential : GKN Driveline

Door Panel Insert: Haartz

Fasterners :PowerTrain and Chassis : Rightway Fasteners

Fuel Tank Straps :Midway products

Leaf Springs: Rassini

stainless steel fasteners : Maclean Fogg

exhaust component : Tennecco

License plate Lamp :Hella

Fuel Tank StrapsMidway products

Monday, January 18, 2016

Review of Storage and Warehousing Supply Chain Start Ups

View post on imgur.com

LIST OF SUPPLY CHAIN WAREHOUSING AND STORAGE START UPS

1.)Lockitron A remote controlled lock and mobile app enabling users to store locally instead of using warehouses.

2.)MakeSpace An on-demand storage solution. MakeSpace provides pickup, urban storage, and on-demand retrieval.

3.)Boxbee Much like MakeSpace, BoxBee provides pickup, urban storage, and on-demand retrieval for homes and businesses through an easy web/mobile interface.

4.)ShareMyStorage On sharemystorage.com people are brought together to provide a common sense self-storage solution – using space such as the attic, garage, basement, or spare room in the back-office.

5.)Cubbyhole An app-based service that lets users rent their storage space out to strangers. Renters specify how much space they need and for how long, and snap a photo of the goods they need to store. Prices start at $15, renters pay via credit card directly through the app

6.)Keycafe Store your keys securely at the local cafe and exchange them remotely with your home-rental guests via the app. Keycafe is not classic ‘storage’ but about managing access to your home remotely.

7.)Swapbox: Shop online and ship your packages to a Swapbox located nearby. It’s a modern, always-open postoffice. You get notified via email and/or text message when your packages arrive.

8.)Cargomatic A platform that provides shippers with instant access and real-time visibility to trucks around them via mobile app and cloud-based software.

TruckTrack A cloud app for trucking business management, giving instant insight into business KPIs, fleet and human resources. The app also provides you business optimization recommendations.

source : Johathanwichmann

Supply Chain Logistics and Transportation Start Ups

Transportation & Logistics Start Ups

Matternet is a transportation system made up of Unmanned Aerial Vehicles (UAVs), landing stations and routing software. The system aims to transform the way we move goods locally, starting with the pharmaceutical delivery market in areas inaccessible by traditional infrastructure.

Freightos A website – and a network of freight forwarders – that provides automated freight quotes and a contract management system for shippers.

Transporteca: A website giving shippers and consignees a much-needed tool to easily compare shipping and transportation prices from freight forwarders.

iContainers: An end-to-end pricing tool and freight forwarding service offering best available prices for ocean and sea freight as well as international moves. With iContainers you can get a quote online instantly from multiple carriers.

Shippo" Shippo is “shipping made easy”. With the Shippo API and apps you can get discounted shipping rates and labels within minutes. Shippo is basically selling discounted labels when connecting shopping cart apps with carriers such as DHL, FedEx and UPS – making things easier and cheaper for those who want to ship.

Retigence : A company specialising in " providing predictive analytics, which will help retail and businesses to align inventory to the real time demand of the product.By mapping inventory in real time it helps retailers predict ' demand forecasting better

Freight Filter An easy-to-use service to help you find the best shipping options. It’s divided into three simple steps – get the price, book it, and ship.

Xeneta A service that ads transparency to the shipping industry by enabling companies to benchmark their ocean freight rates. Useful for both importers, exporters and freight forwarders, e.g. for understanding the market and when negotiating prices.

source :jonathanwichmann

Thursday, January 14, 2016

5 Steps in creating a Sales and Operations (SOP) Planning Process

source :supplychaininsights

The 5 steps in creating a sales and operation Planing are

1) demand planning

2)Supply planning

3)Determine most profitable

4)Conduct If what Analysis

5)Collaborate among cross functional departments

Auditing Supply Change Delays and Disruption: Top 5 Findings

HOW SUPPLY CHAIN RISKS IMPACT COMPANY BOTTOM LINE

A recent research report on the risks of supply chain shows us some startling statistics. Since most manufacturers outsources a fair amount of work to “ their suppliers and vendors” the chance of “ supply chain disruption, delays or external natural factors is always omnipresent .

• However just 25% of a typical company’s end to end supply chain is being assessed for risk auditing The risk factor

• 90% of respondents do not formally quantify risks when sourcing production • In a survey 45% firms indicated a looss of revenue due to supply chain distruption

• 14% of companies revenue loss on account of supply chain distruption exceded one million euros • Supply chain distruption caused shareholder returns to decline by 33-40% over a 3 year period

• Share prices of companies that experience delay and disruption in supply chain tended to be more volatile ( on average around 13.5% higher)

• 58% of firms indicated that a loss of productivity as the main reasons for supply chain disruptions • while 11% firms believed that supply chain risks and delays lead to increase in cost of production

Monday, January 11, 2016

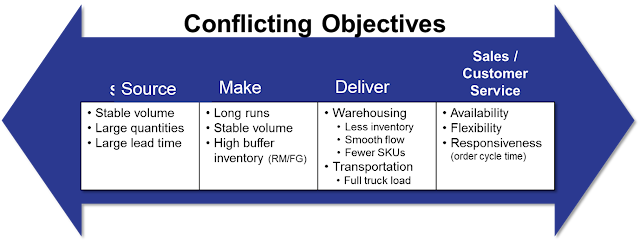

Reviewing Supply Chain Conflicts: Manufacturer Vs Multi-brand Retail

manufacturer vs multi-brand retail is one of the classic cases of supply chain conflicts.

Manufacturer vs multi-brand retail conflicts is one of the most classic cases of supply chain conflict, as the manufacturer will want the retailer to work with high service levels as to ensure availability of his product on the shelf. However, a multi-brand retailer across the world or any big departmental store would want to maintain a high product availability at the category level and not on a brand level.

If the cost of substitution of competing brands is not very high, the departmental store does not mind which brand” is available at the store as long as the category product are available. This model is valid for products that do not have a very high level of brand loyalty. For example “ Milk, Yoghurt, Cheese, Butter, jams, sauces “ which are mostly generic products”

In the above cases, the multi-brand retail chains would like to work on a lower service level as to keep his “overall cost low This substitution model, which the multi chains believe in, is in direct confrontation with the model the manufacturers believe in. However for a single sourced item in a business to business environment, we don’t see the kind of conflicts we see in “ product categories that are more or less “commodities “.

Wednesday, January 6, 2016

Supply Chain Risk; Suppliers Vs Manufacturers

SUPPLY CHAIN RISK: SUPPLIERS VS COMPANY

For companies that manufacture products mostly use suppliers, and over a period of time, they have become extremely dependent on them. So should the supply chain depends on the outsourcing suppliers? Most companies have many suppliers as to derisk their investment and ensuring backup if one supplier goofs up

However, there exist a divided opinion on ultimately who is responsible for " supply chain. Are the suppliers more accountable for the supply chain risk, or is it the supply chain teams of the company more responsible for " ensuring vendors and suppliers" deliver in the right number and the right time

According to The Ripple Effect, a recent survey conducted by Deloitte Consulting LLP, 63% of executives see external suppliers as one of the biggest sources of today’s supply chain concerns. And when problems do arise, it’s the company—not suppliers—that will likely bear the brunt of the blame. What’s more, even having a diversified portfolio of suppliers is no guarantee when it comes to managing the supply chain.

For example, when Japan was hit by a tsunami in 2011, most companies thought their supply chains were safe because they had multiple suppliers as backups. As it turned out, many of those suppliers relied on the same secondary suppliers, causing the entire supply pyramid to collapse.

Top 3 Challenges in Supply Chain for the Food Industry

TOP 3 SUPPLY CHAIN CHALLENGES ACROSS THE FOOD INDUSTRY

Supply chain across Food Industry is a big challenge. The basic problem is in the kind of products across supply chain which is perishable. Unlike other industry the inventory has to be very tightly controlled so that products are fresh and losses minimized

In the past, most food companies dealt with supply chain risk after-the-fact through product recalls—and by switching suppliers once problems were detected. In an increasingly complex marketplace, the traditional approach just isn’t good enough.

Tracing a food problem back to its source is complicated by multi-tiered supply networks and divergent standards for food quality and safety around the world. For example, various countries that produce rice allow different levels of arsenic (which is used to control pests). This means that rice may be deemed safe and legal to sell in one market but not in others. Regulations and standards are continually evolving and present a challenging risk. In the U.S., for instance, federal lawmakers are expanding the authority of the Food and Drug Administration to include the ability to shut down operations that fail to comply with the law.

The supplier in the food industry is a big variable and is a crucial factor in deciding the success of the supply chain, as the raw stock of the food is the most precious and important part of the inventory forecasting. Apart from quality and consistency, adulteration is another risk.The entire ecosystem Farmers, to the cold storage to the suppliers play a big role in ensuring the effectiveness of the supply chain across the Food Industry.

Tuesday, January 5, 2016

The numbers behind the Trucking Industry: Infographic

|

The numbers and data behind the US trucking Industry: top 5 trends |

- Trucking statistics in the United States The trucking industry employs a total of all most 9 million, out of which 3.5 million are truck drivers

- There are currently 62 million unregistered vehicles in the United states and approx 6.4million unregistered Vehicles Out of which 32% consists of heavy vehicles including construction Vehicles, bulldozers, and heavy machinery vehicles out of which 2 million tractor trailers.

- The US economy is heavily dependent on Trucking industry to deliver 70% of freight transported annually

- Approximately 671 billion of manufacturing and retail goods are transported by Trucking industry in one year.Truck Transportation of goods to Canada makes up $295 billion of the truck trade and $195billion with Mexico

- 1 out of 9 truck drivers are independent, a majority which are owner operators Approx 5.7 % of truck drivers in the United States are the woman.

Reviewing Less Than Truckload Shipments

Explaining LTL Shipments (Less than Truckload ) Shipments in Logistics and Transportation

A shipment that does not require a full 48- or 53-foot trailer can be shipped via less-than-truckload or LTL. Shippers use this option, which can be cost-effective and environmentally friendly when they only need to ship a small amount of product.

LTL shipments involve shipment of relatively small freight. To put it in simple terms, general freight carriers offer two types of service, Full Truckload (FTL) service or Less-Than-Truckload (LTL).

While the FTL carrier moves full containers or trucks of one product from one customer, the LTL carrier moves goods from many different customers on one truck.

LTL shipments typically weigh between 151 and 20,000 lb (68 and 9,072 kg). Less than Truckload carriers use "hub and spoke," operations, where small local terminals are the spokes ('end of line') and larger more central terminals, are the hubs (also called Distribution Centers or DC's).

LTL shipment rates s are determined by class, weight, lane (i.e., pickup and delivery locations), and additional required services, if any. LTL carriers normally offer better rates than parcel carriers for competitive reasons and economies of scale. A separate cost added on top of the line haul, the fuel surcharge is the cost of fuel associated with the lane, specifically the distance between the shipper and the consignee. The fuel surcharge changes weekly due to barrel costs.

Reviewing Logistics & Transportation Scheduling: Static Scheduling

Once the vehicle route has been scheduled, the frequency of collection and dispatch not only depends upon the demand and supply but also on other constraints.The firm has to keep in mind the firm has to choose between 2 strategies for optimal utilization of the resource.

Take the example of Amul Dairy and milk marketing cooperative in India. Here schedules are announced in advance and the local farmers know at what time the vehicle will visit their village for milk collection.In other words, it works with static schedules which are pre-decided for milk production

Auto companies to work with static schedules for part collection from their vendors.

Companies like Unilever clusters all dealers into 6 groups and each static group gets served on a working day and even within that day, the route followed by the vehicle is announced well in advance. Static schedules result in, by and large, uniform load on the depot and transport system and helps the dealer in planning the work ahead because the dealer knows the exact slot within a week when delivery can be expected.

Take the example of Amul Dairy and milk marketing cooperative in India. Here schedules are announced in advance and the local farmers know at what time the vehicle will visit their village for milk collection.In other words, it works with static schedules which are pre-decided for milk production

Auto companies to work with static schedules for part collection from their vendors.

Companies like Unilever clusters all dealers into 6 groups and each static group gets served on a working day and even within that day, the route followed by the vehicle is announced well in advance. Static schedules result in, by and large, uniform load on the depot and transport system and helps the dealer in planning the work ahead because the dealer knows the exact slot within a week when delivery can be expected.

Monday, January 4, 2016

Review of Supply Chain: Cross Docking and Best Practices

As we explained Cross Docking here. In this article we look at the benefits of cross docking and across which industry and circumstances can it be used. 1) The first benefit is that it allows manufacturers to prevent costs on warehouses as the incoming materials are directly picked up by outbound trucks.

2) This ensures transportation costs are minimized and kept under control.

However, this concept of cross docking is only possible only if a firm is working in an environment of predictable volumes which lowers transit types. For example, if 3 trucks bring in incoming materials to be loaded onto outgoing 3 trucks, all the 6 trucks must be available at the single point at one destination. if this is not available cross docking cannot take place, otherwise, the firm needs a physical distribution point or a warehouse to take care of the inventories piled up In the absence of cross docking, the manufacturer does not have to tightly control the logistics flow.

And the material can be directly shipped, however in this model the cost of transportation increases. In cross docking the " need for tightly controlling the logistics as it has to ensure that the entire ecosystem has to be tuned in to ensure both incoming and outgoing trucks are available in real time and a predestined point. Walmart is one company that has been using cross docking extensively which has ensured that its transportation costs are kept low. For this reason, Walmart has been using its own vehicles so that it can have more control over the vehicles.

Subscribe to:

Comments (Atom)