share posts

Wednesday, December 30, 2015

Tuesday, December 29, 2015

Reviewing the role of Information Technology in enabling effective Supply Chain decisions

|

INFORMATION TECHNOLOGY AND SUPPLY CHAIN DECISION MAKING |

Information technology plays a huge supporting role in ensuring the right mix of decisions and designs that helps supply chain managers take the right decision

Information technology helps managers to access information on the functions and status of all other supply chain across geographic units.

For example a retail store can not only afford to figure out the store inventory, but also need information on consumer demand, lead times and associate variability’s like “logistic and transportation “

- The IT department provides seamless and friction less support across the supply chain implementation , which forms the core of the supply chain. Any process related to order and purchase, manufacturing , inventory, transportation and logistics , and warehouse are mapped and tracked

- IT provides internal collaboration across departments, which are shared across the internet and cloud . It helps vendors, suppliers and other stakeholders across the supply chain to co-operate and collaborate.

- IT based decisions support systems is used to aid better decisions through the supply chain mechanism and ecosystem. Any critical issue on delivery, demand fluctuations ,lead time and risk can be “ tracked in real time” therefore giving the operational managers, the flexibility and the time to ensure compliance

- The role of Information Technology in terms of measuring the entire supply chain performance and aid the operational managers to set internal metrics and benchmarks and observe “ their effectiveness”cannot be more emphasized. Business Intelligence tools includes a technology stack with layers for reporting and analysis

Supply Chain Application Marketplace Review

|

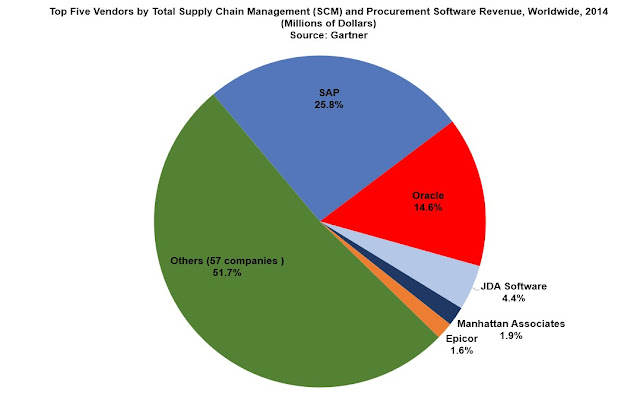

SAP grew their share of the worldwide SCM market from 23.9% in 2013 to 25.8% in 2014. |

There are broadly 4 categories of firms that supply supply chain management application software.

- ERP vendors offering comprehensive solution or a variety of vertical industries

- Independent vendors offering a comprehensive solution for a variety of vertical industries

- Niche Players offering solution for specific supply chain functionalities.

- Niche players offering solution for specific industries

Its important for supply chain managers to understand the interaction between the ERP systems and niche functionality provided by supply chain retailers. Although the supply chain application marketplace players are viewed as competitors they also rely on each other to compliment features and functionalities

Among the major trends in the SC Application Market review is the gradual shift to Cloud-Based (SaaS) Technology .SCMS adoption is growing faster than the broader enterprise application software market. The annual revenue from SCMS (both premise-based and SaaS) reached $10 billion in 2014, a 12 percent increase over 2013.

A recent Gartner projection forecasts 60% of the growth in Supply chain management software (CMS) between 2015 and 2018 will be based on the SaaS subscription model, driven by a growing realization of the benefits of cloud-based services.

The SaaS-based SCMS market grew by about 24% in 2014 and is projected to continue to grow at a 19% (CAGR), reaching $4.4 billion in annual sales by 2018

ERP vendors particularly SAP has added supply chain management functionality to their offering and succeeded in leading the marketshare by a huge margin, and make it difficult for independent or niche players to sell to ERP vendor clients. Further ERP vendors have been developing industry specific supply chain management solutions..and as a result the share of supply chain management software sales going to ERP vendors has risen , while the niche and start ups vendors have drastically been left at the bottom languishing in sales

Monday, December 28, 2015

Reviewing Supply Chain Redesign : Centralization vs Decentralization

HOW CENTRALIZATION AND DECENTRALIZATION OF IMPACT SUPPLY CHAIN REDESIGN

A supply chain redesign has a significant impact on the inventory and supply chain costs. This can be done only by a rigorous cost benefit analysis The centralization and decentralization example also illustrates the benefit of Risk Pooling.

For example a company has 10 regional stock points which it serves its dealers from the stock point that is the closest and wants to centralize its stock holding, which means that the stocks will be held at one point and the retailers would be served from there.

However this arrangement, will increase the transportation costs along with the fact that it cannot force the retailers to hold excess inventory. This means that the company has to work on a much faster transportation and logistics scheme.However this will increase its logistics costs.

Whereas in the decentralization model, the transport costs will be low, but the cost of holding inventory at the companies warehouse will be high.

Thus its essential to do a rigorous and effective costs analysis by “ using a preductive software to estimate demand and supply chain redesign In general whenever we pool demand across locations , the phenomenon of rik pooling may be observed. Risk pooling suggests that demand uncertainity is reduced when one pools demands are spread across location

A supply chain redesign has a significant impact on the inventory and supply chain costs. This can be done only by a rigorous cost benefit analysis The centralization and decentralization example also illustrates the benefit of Risk Pooling.

For example a company has 10 regional stock points which it serves its dealers from the stock point that is the closest and wants to centralize its stock holding, which means that the stocks will be held at one point and the retailers would be served from there.

However this arrangement, will increase the transportation costs along with the fact that it cannot force the retailers to hold excess inventory. This means that the company has to work on a much faster transportation and logistics scheme.However this will increase its logistics costs.

Whereas in the decentralization model, the transport costs will be low, but the cost of holding inventory at the companies warehouse will be high.

Thus its essential to do a rigorous and effective costs analysis by “ using a preductive software to estimate demand and supply chain redesign In general whenever we pool demand across locations , the phenomenon of rik pooling may be observed. Risk pooling suggests that demand uncertainity is reduced when one pools demands are spread across location

Thursday, December 24, 2015

5 Supply Chain Predictions for the Manufacturing Industry

Supply Chain Predictions

International Data Corp (IDC) has predicted that the next four years are likely to see a re-imagining of the manufacturing supply chain process, amid changing customer demands and technology. Here are the IDC top 5 Predictions for global chainThe IDC Future Scape provides the top 10 predictions for global supply chains for 2016.

- Top 10 Supply Chain Predictions: ● By the end of 2016, the majority of all manufacturers will be actively employing eCommerce networks and marketplace model

- By 2018, supply chain will be driven by the proliferation of advanced, purpose-built, analytic applications aligned to the Internet of Things (IoT) will result in 15% productivity

- By 2019, 50% of manufacturers will have modernized their logistics network to leverage 3D printing, robotics, and cognitive computing

- By the end of 2017, the need for visibility, scalability, and flexibility across the value chain will drive 60% of manufacturers to invest in cloud-based WMS and TMS solutions aligned to their trade partner networks.

- By 2018, 40% of manufacturers will be investing in robotics, autonomous guided vehicles (AGVs) and associated systems within their warehousing operations to drive automation into their fulfillment processes.

- By 2020, 50% of the operational jobs in the supply chain will have evolved into “knowledge” roles required to support new technologies like cognitive computing and modern robotics.

Tuesday, December 22, 2015

5 Biggest Supply Chain Challenges for Manufacturers

|

WHAT ARE THE BIGGEST SUPPLY CHAIN CHALLENGES |

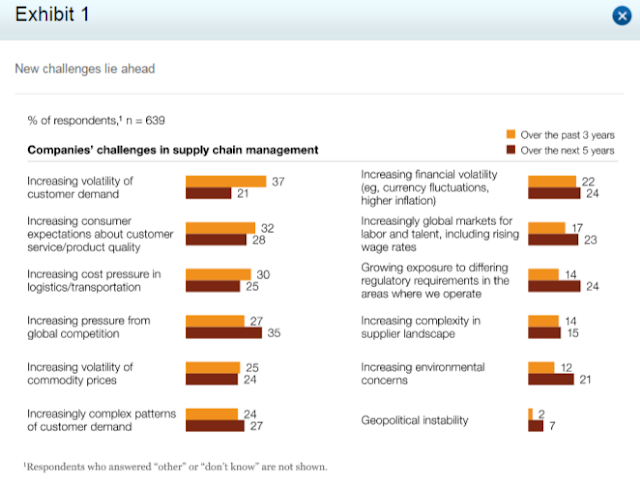

In an McKinsey survey opinions are divided on their companies’ preparedness to meet those challenges, and fully two-thirds expect supply chain challenges risk to increase. This chart shows the top 5 biggest supply chain challenges for manufacturers and retailers across industry

Different organizations in the supply chain may have different, conflicting objectives depending by type

- Manufacturers: Transportation and Shipping Costs Manufacturing and production ,quality control

- Distributors: low inventory, reduced transportation costs, quick replenishment capability

- Retailers:shorter order lead time, stock shortage,high in-stock inventory, no of SKU,efficient inventory management analytical engine Bullwhip effect; One of the most glaring challenges ,in supply chain is the phenomenon of orders and inventories getting progressively larger (Bull whipping happens when ordering/producing is done on large lots which increase the safety stock of suppliers and its corresponding carrying cost.

- Vendors/Suppliers:Uncertainity of vendors,suitability of suppliers

- Omnipresent Supply Chain :The effective presence or lack of an omnipresent supply chain

- Labor and arbitration issues, shortages of labor

Reviewing 5 Trends that will shape supply chain and logistics by 2016

|

5 trends that will shape supply chain and logistics by 2016 |

The next 5 tech frontiers : that will change the supply chain and logistics industry :

1)Algorithm, Remote and real time shipping : Powered by drones, this technology is set to go where no man, machine or android has ever been before.. At the customers doors without a human waiting to deliver goods.

The development of drones has progressed much faster that users expected. Automated Drones with Remote sensing, using powerful algorithms, along with geo targeting,remote sensing capabilities will deliver packages to consumers in flat 60 mins

The top speed of a drone : 50 mph per hour while the max done payload is less than 5 LBS, at this capacity the drone can deliver 86% of Amazons inventory Trend :

How Soon :in very near future within 2-5 years

2)Same day delivery is now MUST ‘ In the early 2012, shipping time used to be one week as a standard. In 2012, around 50% of consumers felt ok to wait seven days ( a week for a package delivery) In 2014, only 35% felt ok with one week deliveries

How soon? An overwhelming 85% believe that same day delivery should be the norm by 2017-18

3)RFID zation of managing inventory by :The RFIP market is further set to grow with increasing consumer online buying.Another step towards industry moving toward internet of things , fuelled by increasing adoption of RFIDs, as they reach the point of sale quickly.An Idtechex research data show that RFID market will be up from $8.9billion in 2014 to $27.31 billion by 2024

4)Real vs Retail : The lines between retail stores and online stores is soon to get blurred : Closer home online retail will have much bigger share of the wallet with more than 10% of all retail sales coming from internet by 2017

infographic: via

Subscribe to:

Posts (Atom)